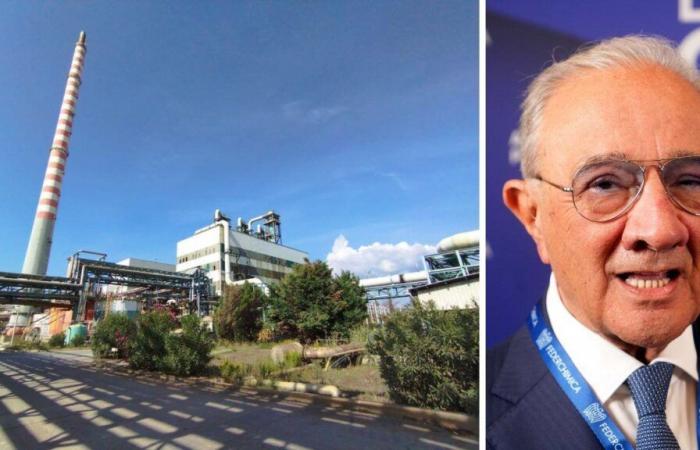

GROSSETO. The newco Sol-Tiox Srl has been ready for some time, 1% controlled by Solmar Group and for 99% from New Solmine. This morning, with the signing of the purchase contract from Venator PlcSol-Tiox will formally take possession of the plant Casone di Scarlinowhere it has been produced for years titanium dioxide (TiO2). It is the happy ending of a troubled story. A story in the course of which many responsibilities have overlapped: from those of the multinational to those of the committees that have always put a spoke in the wheels of the industry, up to the guilty underestimations of politics and the institutional delays. This Monday, however, another story begins, yet to be written and hopefully positive. To take stock of the situation, The Tyrrhenian Sea heard the engineer Luigi Mansi. The co-founder of Nuova Solmine together with Ottorino Lolini e Giuliano BalestriIn fact, right from the start it sensed the great growth opportunities inherent in the unification of the sulfuric acid production business, which Nuova Solmine has been dealing with since 1997, with that of titanium dioxide, in Scarlino produced first by Huntsman Tioxide and then by Venator.

So, engineer, 28 years after taking over the Solmine business, here is a new challenge.

«Yes, in recent weeks we have worked hard on the establishment of Sol-Tiox, which will be absorbed by Nuova Solmine within three years, and on the development of the industrial plan. Nuova Solmine and Sol-Tiox will integrate their production cycles to the maximum, and we will produce sulfuric acid, titanium dioxide and electricity. On the other hand, Venator Italy purchases 200 thousand tons of sulfuric acid per year from Nuova Solmine.”

Is the plant ready to restart?

«Yes, it has been kept in good working order. For this reason we have set ourselves the objective of starting with the first dioxide production line from next January 2nd. Then within three months to activate the second line, and if all goes well by the end of the year to have the plant at full capacity. We considered a production capacity of 20 thousand tons for each line. At the beginning, 134 people will work, followed by all the other former Venator employees.”

How much did it cost to acquire the factory and take on the employees?

«The “working” capital (short-term corporate assets and liabilities, editor’s note) necessary to close this industrial operation is around forty million euros. With this financial commitment we will, for example, take charge of the staff and materials in the warehouse.”

The current CEO of Venator Italy, Stefano Neri, is said to remain with the company. It is true?

«I confirm. We have an excellent opinion of the work he has done. He will remain with us as general manager.”

On January 15th you will sign a program agreement at the Ministry of Made in Italy, what will it focus on?

«It is a framework agreement divided into four major chapters: employability, environmental protection, applied research and plant investments. A program agreement that looks to the future, taking into account that we are a production hub of national interest in the basic chemistry sector.”

Let’s start with employment.

«All current employees of Venator Italy, 200 people, will be hired by Sol-Tiox. When the project is fully operational, considering the employees of Nuova Solmine and those of the subcontracting companies and related industries, there will be over 600 employees attributable to the Solmar Group, for an impact on the territory of around 80 million euros”.

Does the plant need massive investments?

«The factory is already capable of producing titanium dioxide as it is. But the industrial plan took into account the investment of ten million for a first phase of revamping the equipment. Then we’ll see.”

Environment chapter: there is the problem of landfill for the infamous “red chalks”.

«In the meantime we still have residual storage spaces in Montioni and at the foot of the factory. In the first case it is a question of completing the planned environmental restoration. In the second we have spaces relating to an old authorization, and the ten hectares divided into modules to be completed progressively, authorized at the end of 2024 by the Municipality of Scarlino. We estimated that this could be enough for the next six years. In the meantime, we have already defined the project for the reuse of the former Vallina darling in Bagno di Gavorrano, including the alternative road access to the site, with a twenty-year time horizon. We will shortly illustrate it to the local institutions, after which, following the legal procedures, we will file it with the Region. It will take around 15 million euros. Finally, we have already made contact with the Apuan extraction companies for the supply of the “marmettola” used to inert the sulfuric acid residual from processing. An example of a circular economy.”

What does the “research” chapter include?

«We will invest 30 million euros to develop industrial processes to reconcentrate, and therefore reuse, the exhausted sulfuric acid residual from the titanium dioxide extraction cycle. And to recover plasters for different forms of use. The objective is to obtain revenues also from the waste produced by the industrial cycle.”

Getting a factory back up and running means having the raw material available from which to extract titanium dioxide. How are you doing?

«There is a load of ilmenite (the mineral from which titanium dioxide is extracted, editor’s note) per foot of the factory, and we acquired another in northern Europe. But we have already evaluated how to supply the factory, opening discussions with Mozambique. Country rich in raw materials.”

Producing titanium dioxide requires specific know-how, ensured by the workers, but selling the pigment on international markets is another job.

«We also thought about this for some time. The sales network is already 70% set up and we hope to complete it soon. At the moment in Europe, also thanks to industrial stagnation, everything is at a standstill. But from our calculations there is a market for a demand of 300 thousand tons of titanium dioxide, we will be ready when the recovery takes place.”

© ALL RIGHTS RESERVED